As industries worldwide grapple with the challenges of climate change and environmental sustainability, the cutting…

Boosting Productivity, Reducing Waste: The ROI of Digital Inspection

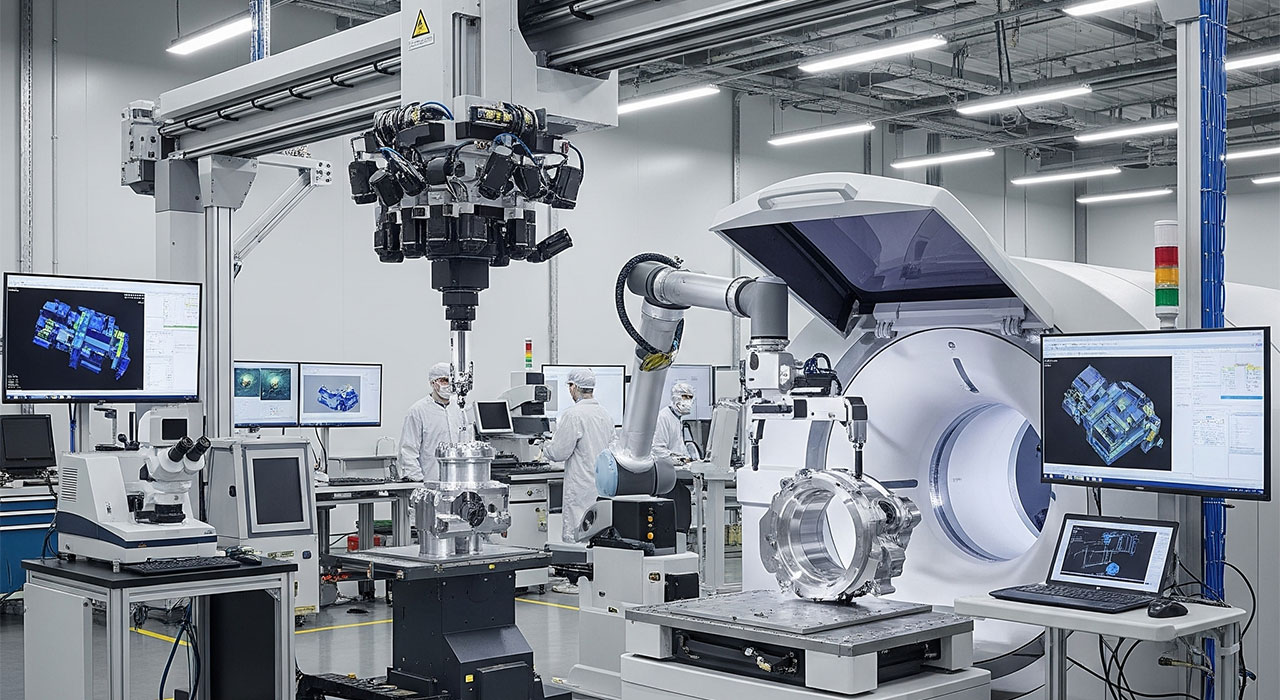

For a long time, precise tool inspection was seen as a luxury, accessible only to large-scale manufacturers with substantial capital and dedicated metrology labs. This is no longer the case. The democratization of advanced manufacturing technology, driven by innovations in compact hardware and flexible software, is empowering small and medium-sized enterprises (SMEs) to embrace digital inspection. This shift is not just about adopting new tools; it’s about making a strategic investment that directly impacts productivity and profitability.

A significant trend is the rise of compact, lower-cost tool presetters. The global market for these devices is expected to grow to 1.5 billion USD by 2030, with a growth rate of 3.9%. These machines, designed with a smaller footprint, allow even the smallest job shops to perform off-machine tool measurement with high accuracy. This capability helps reduce machine downtime by eliminating the need for manual on-machine tool setting, a process that can be both time-consuming and prone to human error. For SMEs in Thane, Maharashtra, and across India, these compact presetters are a game-changer, enabling a level of precision and speed previously unattainable.

Parallel to the hardware revolution, software solutions are transforming how SMEs manage quality control. The emergence of Software-as-a-Service (SaaS) inspection platforms has made powerful analytics and data management tools affordable. The global inspection management software market, valued at 9.2 billion USD in 2024, is projected to grow at a compound annual growth rate of 13.2% through 2030, with the SME segment expected to be the fastest growing. Instead of a large, one-time software license fee, businesses can pay a monthly or annual subscription, lowering the financial barrier to entry. These cloud-based platforms centralize inspection data, simplify audits and calibrations, and provide key performance indicator (KPI) dashboards that help small business owners make data-driven decisions.

Portable probes are another key technology in this movement. The portable metrology equipment market, valued at 400 million USD in 2025, is projected to experience robust growth at a CAGR of over 10% through 2033. These handheld devices provide flexibility and on-demand measurement capabilities directly on the shop floor. They are particularly valuable for quick checks and for inspecting tools or fixtures that are difficult to move. This portability, combined with digital connectivity, allows for immediate data capture and integration into the broader inspection ecosystem, ensuring that every measurement contributes to a complete quality record.

The impact of these affordable technologies is visible in market trends. More than 40% of global manufacturers now use real-time digital inspection for quality control, and the digital inspection market as a whole is valued at over 24 billion USD. For SMEs, particularly in regions with high manufacturing growth like Asia-Pacific, which holds over one-third of the global inspection equipment market share, these scaled solutions are becoming a primary driver of investment.

Ultimately, the democratization of tool inspection is about empowering SMEs to achieve a faster return on investment (ROI). By reducing scrap, shortening setup times, and providing actionable data, these technologies turn inspection from a necessary cost center into a productivity lever. The shift in the market is clear: companies of all sizes are looking for modular, connected inspection capabilities that directly translate to improved operational efficiency and a competitive advantage in a demanding global market.