As industries worldwide grapple with the challenges of climate change and environmental sustainability, the cutting…

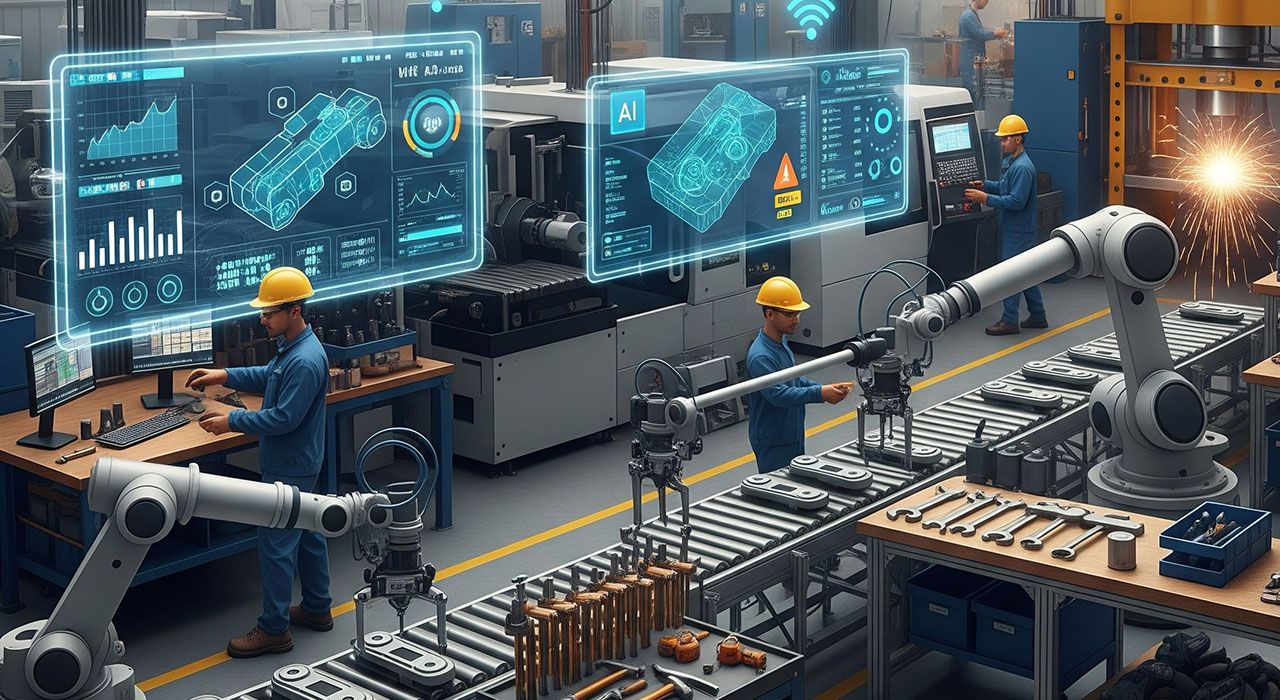

AI and IoT in Tool Inspection: Predictive Maintenance and Real-Time Monitoring

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is revolutionizing tool inspection, moving it beyond simple measurement into an era of predictive maintenance and real-time monitoring. This technological convergence is transforming shop floors in Thane, Maharashtra, India, and globally, offering unprecedented levels of efficiency and precision in manufacturing operations.

The traditional approach to tool inspection often involved periodic manual checks, leading to potential delays in identifying tool wear and the risk of producing defective parts. However, with the advent of IoT-enabled sensors embedded in cutting tools and tool holders, real-time data on parameters such as vibration, temperature, and cutting forces can be continuously collected. This stream of data forms the foundation for AI algorithms to analyze and interpret tool health.

AI algorithms play a crucial role in identifying subtle patterns and anomalies in the sensor data that may indicate early signs of tool wear or potential failure. By learning from historical data and real-time inputs, AI can predict the remaining useful life of a tool with increasing accuracy. This capability enables proactive tool replacement, minimizing unexpected machine downtime, reducing scrap rates, and optimizing production schedules. For manufacturers in Thane and beyond, this translates to significant cost savings and enhanced operational efficiency.

IoT infrastructure facilitates seamless connectivity between tools, machines, and central monitoring systems. This interconnectedness allows for the immediate transmission of sensor data to AI-powered analytics platforms. Operators and maintenance personnel can access real-time dashboards providing insights into the condition of their tools. Alerts can be automatically triggered when a tool is nearing the end of its life or if abnormal operating conditions are detected, allowing for timely intervention.

The benefits of AI and IoT in tool inspection extend beyond predictive maintenance. Real-time monitoring provides valuable feedback on the machining process itself. By analyzing cutting forces and vibration data, manufacturers can optimize cutting parameters for different materials and operations, leading to improved tool life and surface finish quality. This data-driven approach enables continuous process improvement and better control over the manufacturing outcome.

Furthermore, the integration of AI and IoT supports the trend towards automation in manufacturing. Smart tool holders equipped with sensors and connected to intelligent systems can automatically adjust cutting parameters or even initiate tool changes when necessary, reducing the need for manual intervention. This is particularly beneficial for running unattended or lights-out operations, maximizing machine utilization and overall productivity.

For industries in India, such as automotive component manufacturing, precision engineering, and aerospace, the adoption of AI and IoT in tool inspection offers a pathway to enhanced competitiveness in the global market. The ability to predict tool failures, optimize machining processes, and ensure consistent product quality are crucial factors in meeting stringent industry standards and customer demands.

However, the successful implementation of AI and IoT in tool inspection requires careful consideration of data security, infrastructure investment, and the need for skilled personnel to manage and interpret the data generated. Nevertheless, the potential returns in terms of reduced costs, increased efficiency, and improved quality make this technological evolution a compelling proposition for manufacturers looking to future-proof their operations. As AI algorithms become more sophisticated and IoT infrastructure becomes more accessible, the integration of these technologies will continue to drive innovation and efficiency on the shop floor.